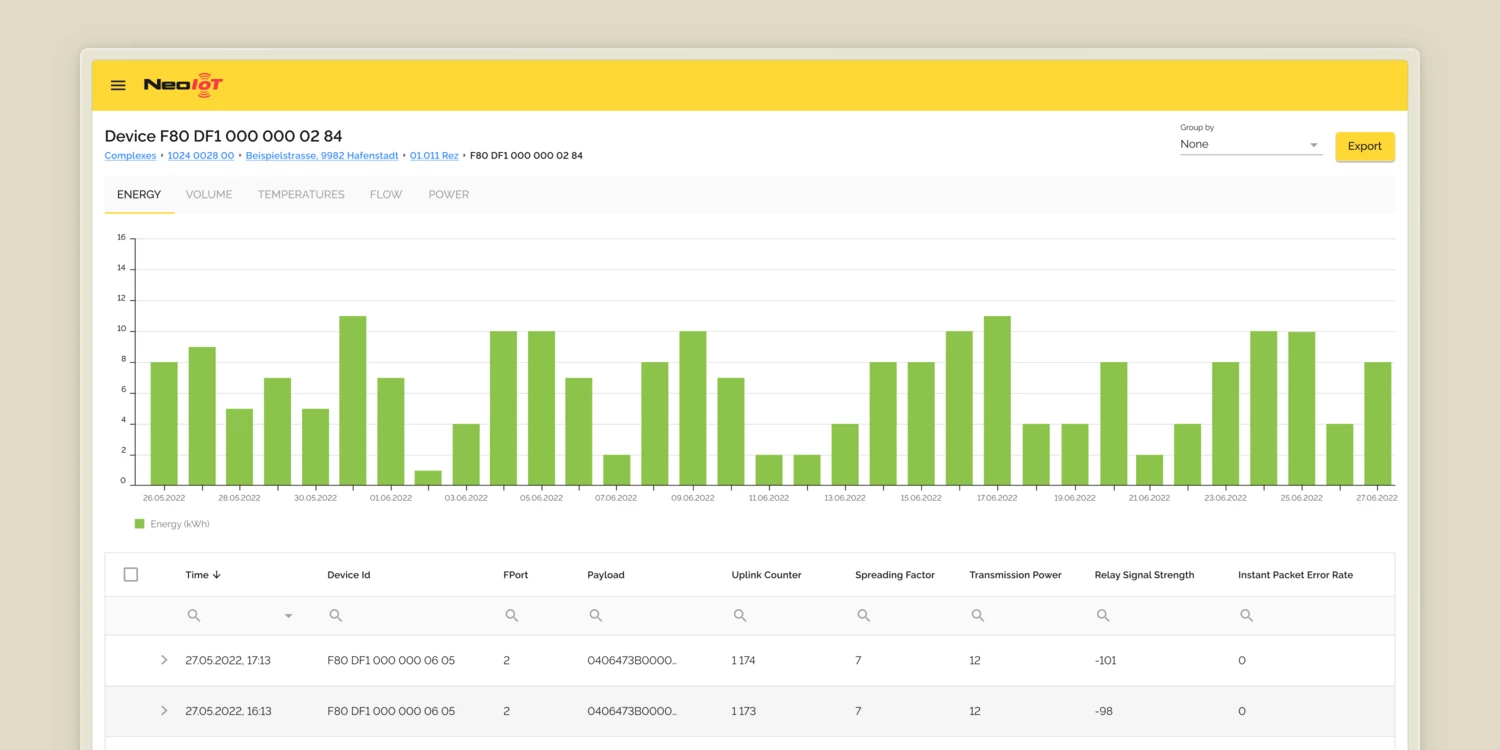

The NeoIoT device portal supports the engineering team in the commissioning and support of several thousand measuring devices. This saves time and improves quality through the preventive detection of incorrectly installed or defective devices.

The project started with the development of a technical prototype to demonstrate the benefits. In the second step, NeoIoT was put on a stable basis to implement further functions.

NeoVac measures and calculates the energy and water consumption for over 400,000 homes in Switzerland. With its portfolio, NeoVac AG covers the complete spectrum from measuring devices to energy monitoring.

Our services

Outcomes

Automatic calculation of the signal quality

The device portal not only shows all devices and their locations, but also their signal quality. An algorithm calculates how long a radio transmission takes for a certain amount of data and at what power the data is sent.

With the help of the algorithm, »faulty devices« are also displayed and can be replaced at the next opportunity.

Current data from 48,500 meters available at all times

The algorithms of the device portal process extremely large volumes of data. Information from around 48 500 devices flows into the system every quarter of an hour. The trend is rising, as NeoVac plans to soon use 1,000,000 devices and retrieve the data every minute.

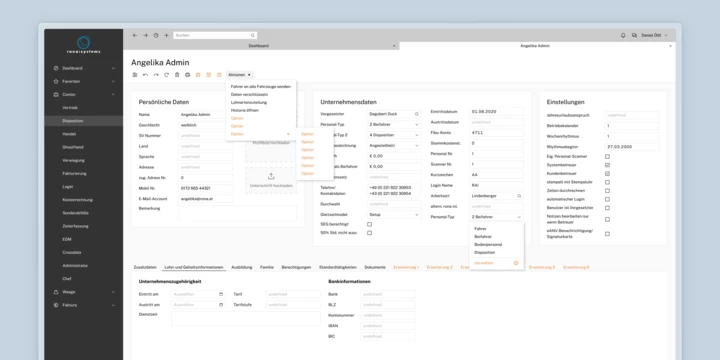

The measured data can be viewed at any time per meter. The raw meter data is converted into a uniform format, matching the protocols and standards implemented by the meter.

Control and transparency reduce risks

Just 24 hours after commissioning, NeoIoT detects whether a device is working. Previously, this process took around 30 days. As a result, the response time has been greatly reduced and the error rate has dropped from 15% to less than 1%.

The experts can react quickly to defective devices and rely on the transparency in the device portal for follow-up support.

Authentication via passwordless login

Users request a link each time they log in, which is sent to them by e-mail. To log in to the device portal, they simply click on the link and are taken directly to the portal.

Tech highlights

The sophisticated technology makes everyday tasks more efficient and retrieving thousands of messages easier.

Technologies used

»Fusonic quickly recognized our need and implemented it in record time. Looking back, I have to say I consider that an extraordinary achievement.«