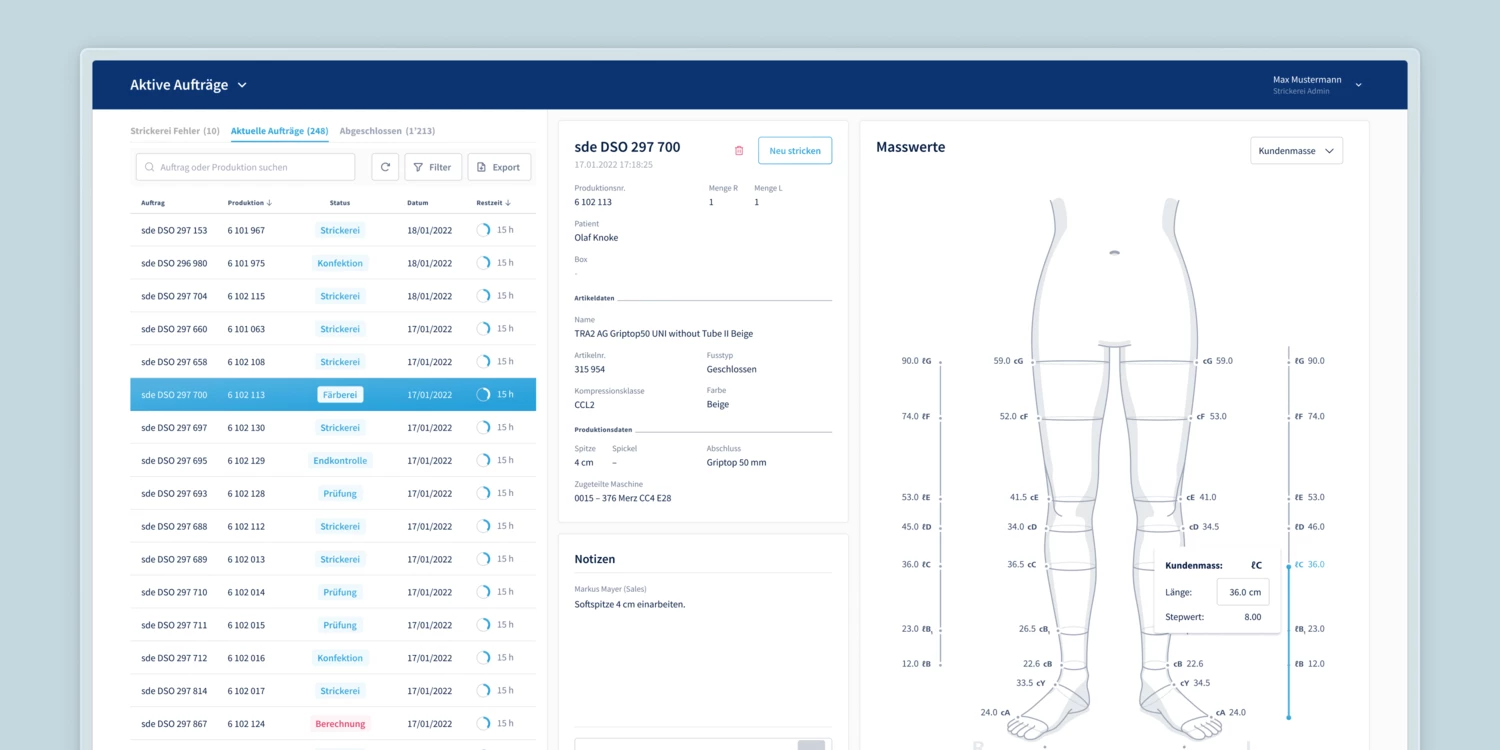

SIGVARIS AG compression stockings are custom-made for each order. In order to meet the high quality requirements and to deliver quickly, the production software controls all steps of the made-to-measure production.

M2 calculates the knitting parameters from the customer's measurement, writes the machine program and provides each specialist with exactly the info and functions they need.

SIGVARIS AG ist ein Medizintechnikunternehmen mit Sitz in St. Gallen, das sich auf Kompressionslösungen spezialisiert hat. Mit über 1600 Fachkräften und Vertriebspartnern agieren sie in mehr als 70 Ländern weltweit.

Our services

- Strategy & Design

- Usability Testing

- Requirements Engineering

- Software Development

Outcomes

Improve processes and test ideas

Efficient and error-free - these are the requirements of process optimization. To ensure that orders flow seamlessly through the departments from receipt to dispatch, M2 production software optimizes processes and helps every specialist to perform their tasks intuitively. In fact, it takes more than just a clear presentation of information. We analyzed the complex work steps during company tours with SIGVARIS AG and jointly developed ideas for optimizing the processes and for a user-friendly design. To sharpen the ideas, they had to prove themselves in additional prototypes and usability testing.

In this way, we also improved the processes away from the application and eliminated risks even before we wrote the first line of code.

Usability testing and collecting feedback

With our usability testing, we promote innovative ideas as well as technologies and test their feasibility with real users. From the impressions and processes we had gathered during the company tours at SIGVARIS AG, we developed design prototypes for all processing steps. To see how the designs worked in reality and to identify potential weaknesses, we observed the teams again and further optimized the processes.

Especially when it comes to troubleshooting, the specialists bring in essential know-how. The expert view creates clarity in the shortest possible time, which is why the design of our production software supports the specialists in checking and initiating the next steps.

Automate and specify knitting process

Since the compression solutions are medical devices, they are subject to the EU Medical Device Regulation and must meet certain standards:

- correct calculation of production values to ensure the desired compression and the required pressure drop.

- traceability of the production steps

- spot checks to constantly meet quality requirements

M2 also helps with this: The production software checks the orders from the ERP system and automatically assigns them to the knitting machines. To do this, M2 is guided by predefined criteria. The software uses the customer measurements and calibration data to calculate the production values and writes the machine program. The machine is instructed how many rows it must knit and how quickly it must incorporate the printing yarn.

Detect and resolve sources of error

98% of all orders pass through production without errors. For the remaining 2%, M2 helps to reduce the error rate and compensate for the loss of time: In order to restart faulty productions as quickly as possible and deliver them on time, the Knitting Admin takes over the manual error correction. This task requires expertise and experience. The process is quick and simple: check for errors, fix them and restart production.

The Knitting Factory Admin handles the error message per job - the global calibration data remains unaffected. Each error is recorded, so recurring errors can be tracked down and their sources corrected.

Tech highlights

Using innovative practices and technologies, we implement a modern application that integrates seamlessly into the existing system landscape of SIGVARIS AG.

Used technologies

»Working with Fusonic has been fun from the beginning, both on a professional and personal level. What I really appreciate is the complete transparency towards us as a client and the way they implement projects, very structured and professional.«